●Ultra-fine Cemented Carbide

●Suitable for Stainless Steel, various Steel Alloy and Steel machining

●Realize high efficiency processing in the way of large cutting

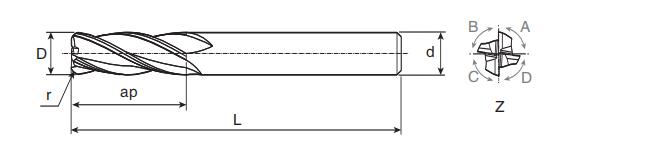

●4F, Radius, X coating, Unequal indexing, Multiple helix

●Unique design maximizes chip removal and improves productivity in slotting and heavy profiling operations.

●Recommend Application: Rough and Semi-Finish processing for Stainless Steel

| P/N |

Flute Dia. (mm) |

Flute Length

(mm)

|

Shank Dia.

(mm)

|

Overall Length (mm) | F# | Tip | Coating |

| GCP435 040 F2 25 055 R050 X | 4 | 10 | 6 | 55 | 4 | R0.5 | Microkevlar X |

| GCP435 050 F2 24 055 R050 X | 5 | 12 | 6 | 55 | 4 | R0.5 | Microkevlar X |

| GCP435 050 F2 24 055 R100 X | 5 | 12 | 6 | 55 | 4 | R1 | Microkevlar X |

| GCP435 060 D 20 055 R050 X | 6 | 12 | 6 | 55 | 4 | R0.5 | Microkevlar X |

| GCP435 060 D 20 055 R100 X | 6 | 12 | 6 | 55 | 4 | R1 | Microkevlar X |

| GCP435 060 D 20 055 R150 X | 6 | 12 | 6 | 55 | 4 | R1.5 | Microkevlar X |

| GCP435 060 D 20 055 R200 X | 6 | 12 | 6 | 55 | 4 | R2 | Microkevlar X |

| GCP435 080 D 20 060 R050 X | 8 | 16 | 8 | 60 | 4 | R0.5 | Microkevlar X |

| GCP435 080 D 20 060 R100 X | 8 | 16 | 8 | 60 | 4 | R1 | Microkevlar X |

| GCP435 080 D 20 060 R150 X | 8 | 16 | 8 | 60 | 4 | R1.5 | Microkevlar X |

| GCP435 080 D 20 060 R200 X | 8 | 16 | 8 | 60 | 4 | R2 | Microkevlar X |

| GCP435 100 D 20 075 R050 X | 10 | 20 | 10 | 75 | 4 | R0.5 | Microkevlar X |

| GCP435 100 D 20 075 R100 X | 10 | 20 | 10 | 75 | 4 | R1 | Microkevlar X |

| GCP435 100 D 20 075 R150 X | 10 | 20 | 10 | 75 | 4 | R1.5 | Microkevlar X |

| GCP435 100 D 20 075 R200 X | 10 | 20 | 10 | 75 | 4 | R2 | Microkevlar X |

| GCP435 120 D 20 075 R050 X | 12 | 24 | 12 | 75 | 4 | R0.5 | Microkevlar X |

| GCP435 120 D 20 075 R100 X | 12 | 24 | 12 | 75 | 4 | R1 | Microkevlar X |

| GCP435 120 D 20 075 R150 X | 12 | 24 | 12 | 75 | 4 | R1.5 | Microkevlar X |

| GCP435 120 D 20 075 R200 X | 12 | 24 | 12 | 75 | 4 | R2 | Microkevlar X |

| GCP435 160 D 20 100 R100 X | 16 | 32 | 16 | 100 | 4 | R1 | Microkevlar X |

| GCP435 160 D 20 100 R150 X | 16 | 32 | 16 | 100 | 4 | R1.5 | Microkevlar X |

| GCP435 160 D 20 100 R200 X | 16 | 32 | 16 | 100 | 4 | R2 | Microkevlar X |

| GCP435 160 D 20 100 R250 X | 16 | 32 | 16 | 100 | 4 | R2.5 | Microkevlar X |

| GCP435 160 D 20 100 R300 X | 16 | 32 | 16 | 100 | 4 | R3 | Microkevlar X |

| GCP435 200 D 20 100 R100 X | 20 | 40 | 20 | 100 | 4 | R1 | Microkevlar X |

| GCP435 200 D 20 100 R150 X | 20 | 40 | 20 | 100 | 4 | R1.5 | Microkevlar X |

| GCP435 200 D 20 100 R200 X | 20 | 40 | 20 | 100 | 4 | R2 | Microkevlar X |

| GCP435 200 D 20 100 R250 X | 20 | 40 | 20 | 100 | 4 | R2.5 | Microkevlar X |

| GCP435 200 D 20 100 R300 X | 20 | 40 | 20 | 100 | 4 | R3 | Microkevlar X |

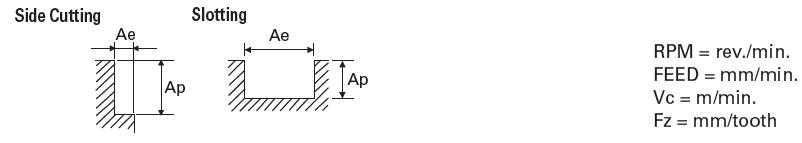

| GCP435R Speed and Recommendations | |||||||||||||

|

ISO GROUP |

CMG |

Type of cut |

ap*Dc |

ae*Dc |

Vc |

Parameters |

4 | 6 | 8 | 10 | 12 | 16 | 20 |

| P |

P 1-2 |

Side Milling |

1.5 | 0.5 |

152 130-168 |

RPM | 12125 | 8080 | 6060 | 5345 | 4450 | 3340 | 2670 |

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 395 | 520 | 665 | 820 | 835 | 710 | 695 | ||||||

|

Slotting |

1 | 1 |

112 91-135 |

RPM | 9710 | 6470 | 4850 | 3880 | 3240 | 2430 | 1783 | ||

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 310 | 414 | 523 | 589 | 609 | 515 | 463 | ||||||

|

P 3-4 |

Side Milling |

1 | 0.5 |

107 95-130 |

RPM | 8485 | 5655 | 4240 | 3740 | 3100 | 2330 | 1870 | |

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 275 | 365 | 460 | 575 | 580 | 490 | 485 | ||||||

|

Slotting |

1 | 1 |

99 84-114 |

RPM | 7880 | 5250 | 3940 | 3150 | 2630 | 1970 | 1576 | ||

| Fz | 0.008 | 0.016 | 0.027 | 0.038 | 0.047 | 0.053 | 0.065 | ||||||

| F | 252 | 336 | 425 | 478 | 494 | 417 | 409 | ||||||

|

P 5-6 |

Side Milling |

1 | 0.5 |

70 60-81 |

RPM | 5090 | 3395 | 2545 | 2240 | 1860 | 1400 | 1120 | |

| Fz | 0.006 | 0.011 | 0.019 | 0.027 | 0.032 | 0.037 | 0.045 | ||||||

| F | 115 | 150 | 190 | 240 | 240 | 205 | 200 | ||||||

|

Slotting |

1 | 1 |

61 55-67 |

RPM | 4850 | 3240 | 2430 | 1940 | 1620 | 1210 | 971 | ||

| Fz | 0.006 | 0.011 | 0.019 | 0.027 | 0.032 | 0.037 | 0.045 | ||||||

| F | 116 | 142 | 184 | 209 | 207 | 179 | 174 | ||||||

| K |

K 12-13 |

Side Milling |

1 | 0.5 |

130

-->

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702 | ||||||||