●Ultra-fine Cemented Carbide

●Suitable for HIGH SPEED Aluminum Alloy machining

●3F, Square end, K coating, High Speed milling

●The engineered geometry with Microkevlar K coating allows exceptional metal removal, widely used on aerospace structure and large medical structure

●Recommend Application: High speed rough machining for Aluminum Alloy

| P/N |

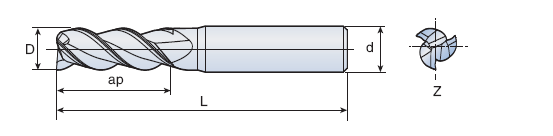

D

(mm)

|

ap

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| A338 040 D 30 050 S K | 4 | 12 | 4 | 50 | 3 | SQ | Microkevlar K |

| A338 040 F2 30 050 S K | 4 | 12 | 6 | 50 | 3 | SQ | Microkevlar K |

| A338 060 D 26 060 S K | 6 | 16 | 6 | 60 | 3 | SQ | Microkevlar K |

| A338 060 D 33 060 S K | 6 | 20 | 6 | 60 | 3 | SQ | Microkevlar K |

| A338 080 D 25 060 S K | 8 | 20 | 8 | 60 | 3 | SQ | Microkevlar K |

| A338 100 D 25 075 S K | 10 | 25 | 10 | 75 | 3 | SQ | Microkevlar K |

| A338 120 D 25 075 S K | 12 | 30 | 12 | 75 | 3 | SQ | Microkevlar K |

| A338 160 D 28 100 S K | 16 | 45 | 16 | 100 | 3 | SQ | Microkevlar K |

| A338 200 D 22 100 S K | 20 | 45 | 20 | 100 | 3 | SQ | Microkevlar K |

| A338 Speed and Recommendations | ||||||||||||

|

ISO GROUP |

CMG |

Type of cut |

ap*Dc |

ae*Dc |

Vc |

Parameters |

6 | 8 | 10 | 12 | 16 | 20 |

| N | N16 |

Side Milling |

1 | 0.5 |

550

450-760

|

RPM | 29193 | 21894 | 17515 | 14596 | 10947 | 8757 |

| Fz | 0.12 | 0.16 | 0.2 | 0.24 | 0.32 | 0.4 | ||||||

| F | 10509 | 10509 | 10509 | 10509 | 10509 | 10509 | ||||||

|

Slotting |

0.5 | 1 |

550

450-760

|

RPM | 29193 | 21894 | 17515 | 14596 | 10947 | 8757 | ||

| Fz | 0.09 | 0.12 | 0.15 | 0.18 | 0.24 | 0.3 | ||||||

| F | 7882 | 7882 | 7882 | 7882 | 7882 | 7882 | ||||||

|

Slotting |

1 | 1 |

340

225-450

|

RPM | 18046 | 13535 | 10828 | 9023 | 6767 | 5414 | ||

| Fz | 0.06 | 0.08 | 0.10 | 0.12 | 0.16 | 0.20 | ||||||

| F | 3248 | 3248 | 3248 | 3248 | 3248 | 3248 | ||||||

| Machine | Machine:FIDIA | ||||

| Power(KW) | 120 | Spindle speed | 30000 | ||

| Holder | HSK100 | Collet | Hydraulic | ||

| Fixture | Special | Working way | Slotting, Side milling | ||

| Workpiece | Name | Aeroplane Wing Rib | P/N | ||

| Material | 2050 T84 | Heat treatment | □ Yes | ||

| Spec. | Hardness: HRC__ | ||||

| Discription | 3F, 12MM, Square | 3F, 16MM, Square, with Neck | |||

| Brand | Couloir Cutter | Couloir Cutter | |||

| P/N | A338120D25075SK | AN338160E15150SK | |||

| Flute#/Coating | 3F,Microkevlar K | 3F,Microkevlar K | |||

| Spindle Speed(RPM) | 17000rev/min | 11000rev/min | |||

| Depth of Cut(ap) | 6mm | 16mm | |||

| Width of Cut(ae) | 12mm | 8mm | |||

| Cutting speed(Vc) | 640m/min | 550m/min | |||

| Feed per tooth(CTP) | 0.196mm | 0.3mm | |||

| Feed (F) | 10000mm/min | 10000mm/min | |||

| Cutter reach | 30mm | 30mm | |||

| Cooling | Air | Air | |||

| Tool life |

Continuous processing for more than 20 hours |

Continuous processing for more than 20 hours | |||

| Conclusion |

Besides realizing high speed and big removal rate on aerospace alumium part, A338 still apply to medical structure and big general mechanical structure. |

||||

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1