●Diameter 1mm~12mm with 5D~12D flute length

●Suitable for Stainless Steel and Steel, HRC62

●4F, Square end, X coating, High hardness

●Designed specifically for the ULTRA-LONG cutting. Verified TINY TAPER on flute minimize tool offset during machining.

●Recommend Application: High speed & High hardness processing

| P/N |

D

(mm)

|

ap

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| S430 010 F2 50 060 S X | 1 | 5 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 010 F2 80 060 S X | 1 | 8 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 010 F2 100 060 S X | 1 | 10 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 010 F2 120 060 S X | 1 | 12 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 012 F2 50 060 S X | 1.2 | 6 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 012 F2 66 060 S X | 1.2 | 8 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 012 F2 83 060 S X | 1.2 | 10 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 012 F2 100 060 S X | 1.2 | 12 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 015 F2 53 060 S X | 1.5 | 8 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 015 F2 66 060 S X | 1.5 | 10 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 015 F2 80 060 S X | 1.5 | 12 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 015 F2 106 060 S X | 1.5 | 16 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 020 F2 50 060 S X | 2 | 10 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 020 F2 70 060 S X | 2 | 14 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 020 F2 80 060 S X | 2 | 16 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 025 F2 48 060 S X | 2.5 | 12 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 025 F2 80 060 S X | 2.5 | 20 | 6 | 60 | 4 | SQ | Microkevlar X |

| S430 030 F2 53 070 S X | 3 | 16 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 030 F2 66 070 S X | 3 | 20 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 030 F2 86 070 S X | 3 | 26 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 030 F2 100 070 S X | 3 | 30 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 040 F2 50 070 S X | 4 | 20 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 040 F2 65 070 S X | 4 | 26 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 040 F2 75 070 S X | 4 | 30 | 6 | 70 | 4 | SQ | Microkevlar X |

| S430 050 F2 60 080 S X | 5 | 30 | 6 | 80 | 4 | SQ | Microkevlar X |

| S430 060 D 50 080 S X | 6 | 40 | 6 | 90 | 4 | SQ | Microkevlar X |

| S430 080 D 62 100 S X | 8 | 50 | 8 | 100 | 4 | SQ | Microkevlar X |

| S430 100 D 50 100 S X | 10 | 50 | 10 | 100 | 4 | SQ | Microkevlar X |

| S430 120 D 41 100 S X | 12 | 50 | 12 | 100 | 4 | SQ | Microkevlar X |

| S430Speed and Recommendations | |||||||||

|

ISO GROUP |

CMG |

Type of cut |

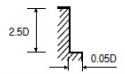

ap*Dc |

ae*Dc |

Parameters |

1 | 2 | 4 | 6 |

| P |

P 1-2 |

Side Milling |

2.5 | 0.05 | RPM | 19200 | 10580 | 6000 | 4420 |

| Fz | 0.002 | 0.006 | 0.014 | 0.029 | |||||

| F | 180 | 240 | 335 | 515 | |||||

| Vc | 60 | 66 | 75 | 83 | |||||

|

P 3-4 |

Side Milling |

2.5 | 0.05 | RPM | 10940 | 6050 | 3410 | 2520 | |

| Fz | 0.002 | 0.004 | 0.010 | 0.021 | |||||

| F | 70 | 95 | 140 | 215 | |||||

| Vc | 34 | 38 | 43 | 48 | |||||

|

P 5-6 |

Side Milling |

2.5 | 0.05 | RPM | 6720 | 3780 | 2150 | 1640 | |

| Fz | 0.001 | 0.004 | 0.008 | 0.017 | |||||

| F | 35 | 55 | 70 | 110 | |||||

| Vc | 21 | 24 | 27 | 31 | |||||

| K |

K 12-15 |

Side Milling |

2.5 | 0.05 | RPM | 19200 | 10580 | 6000 | 4420 |

| Fz | 0.002 | 0.006 | 0.014 | 0.029 | |||||

| F | 180 | 240 | 335 | 515 | |||||

| Vc | 60 | 66 | 75 | 83 | |||||

Machine

Machine: DMU 60P

Power(KW)

28

Spindle speed

18000

Holder

HSK63

Type

Powerful chuck

Fixture

Special

Working way

Slotting, Side milling

Workpiece

Name

Rocket Engine Part

P/N

Material

Chromium Bronze

Heat treatment

□ Yes

Spec.

Hardness: HRC__

Discription

4F, 1mm with 8mm flute length

4F, 1.5mm with 8mm flute length

Brand

Couloir Cutter

Couloir Cutter

P/N

S430010F250080SX

S430015F253060X

Flute#/Coating

4F,Microkevlar X

4F,Microkevlar X

Spindle Speed(RPM)

10000rev/min

12000rev/min

Depth of Cut(ap)

6mm

6mm

Width of Cut(ae)

1mm

0.2mm

Cutting speed(Vc)

314m/min

565m/min

Feed per tooth(CTP)

0.025mm

0.021mm

Feed (F)

1000mm/min

1000mm/min

Cutter reach

25mm

25mm

Cooling

Air

Air

Tool life

1pce

1pce

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1