●Premium grade carbide

●Suitable for Stainless Steel, Steel Alloy and Cast iron.

●2F, Radius, D coating, General purpose

●With big helix angle and strong edge, it can handle with low power machine and poor working conditions

●Recommend Application: General machining

| P/N |

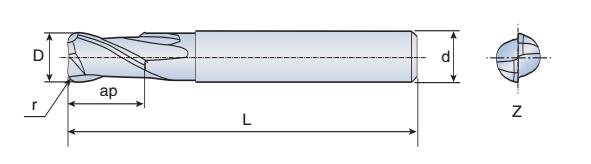

D

(mm)

|

ap

(mm)

|

ND

(mm)

|

H

(mm)

|

d

(mm)

|

L

(mm)

|

F# | Tip | Coating |

| CN230 060 E 15 100 R050 D | 6 | 9 | 5.8 | 50 | 6 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 060 E 15 100 R100 D | 6 | 9 | 5.8 | 50 | 6 | 100 | 2 | R1 | Microkevlar D |

| CN230 060 E 15 125 R050 D | 6 | 9 | 5.8 | 80 | 6 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 060 E 15 125 R100 D | 6 | 9 | 5.8 | 80 | 6 | 125 | 2 | R1 | Microkevlar D |

| CN230 080 E 15 100 R050 D | 8 | 12 | 7.8 | 50 | 8 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 080 E 15 100 R100 D | 8 | 12 | 7.8 | 50 | 8 | 100 | 2 | R1 | Microkevlar D |

| CN230 080 E 15 100 R200 D | 8 | 12 | 7.8 | 50 | 8 | 100 | 2 | R2 | Microkevlar D |

| CN230 080 E 15 125 R050 D | 8 | 12 | 7.8 | 80 | 8 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 080 E 15 125 R100 D | 8 | 12 | 7.8 | 80 | 8 | 125 | 2 | R1 | Microkevlar D |

| CN230 080 E 15 125 R200 D | 8 | 12 | 7.8 | 80 | 8 | 125 | 2 | R2 | Microkevlar D |

| CN230 080 E 15 150 R050 D | 8 | 12 | 7.8 | 100 | 8 | 150 | 2 | R0.5 | Microkevlar D |

| CN230 080 E 15 150 R100 D | 8 | 12 | 7.8 | 100 | 8 | 150 | 2 | R1 | Microkevlar D |

| CN230 080 E 15 150 R200 D | 8 | 12 | 7.8 | 100 | 8 | 150 | 2 | R2 | Microkevlar D |

| CN230 100 E 15 100 R050 D | 10 | 15 | 9.6 | 50 | 10 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 100 E 15 100 R100 D | 10 | 15 | 9.6 | 50 | 10 | 100 | 2 | R1 | Microkevlar D |

| CN230 100 E 15 100 R200 D | 10 | 15 | 9.6 | 50 | 10 | 100 | 2 | R2 | Microkevlar D |

| CN230 100 E 15 125 R050 D | 10 | 15 | 9.6 | 80 | 10 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 100 E 15 125 R100 D | 10 | 15 | 9.6 | 80 | 10 | 125 | 2 | R1 | Microkevlar D |

| CN230 100 E 15 125 R200 D | 10 | 15 | 9.6 | 80 | 10 | 125 | 2 | R2 | Microkevlar D |

| CN230 100 E 15 150 R050 D | 10 | 15 | 9.6 | 100 | 10 | 150 | 2 | R0.5 | Microkevlar D |

| CN230 100 E 15 150 R100 D | 10 | 15 | 9.6 | 100 | 10 | 150 | 2 | R1 | Microkevlar D |

| CN230 100 E 15 150 R200 D | 10 | 15 | 9.6 | 100 | 10 | 150 | 2 | R2 | Microkevlar D |

| CN230 120 E 15 100 R050 D | 12 | 18 | 11.5 | 50 | 12 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 120 E 15 100 R100 D | 12 | 18 | 11.5 | 50 | 12 | 100 | 2 | R1 | Microkevlar D |

| CN230 120 E 15 100 R200 D | 12 | 18 | 11.5 | 50 | 12 | 100 | 2 | R2 | Microkevlar D |

| CN230 120 E 15 100 R300 D | 12 | 18 | 11.5 | 50 | 12 | 100 | 2 | R3 | Microkevlar D |

| CN230 120 E 15 125 R050 D | 12 | 18 | 11.5 | 80 | 12 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 120 E 15 125 R100 D | 12 | 18 | 11.5 | 80 | 12 | 125 | 2 | R1 | Microkevlar D |

| CN230 120 E 15 125 R200 D | 12 | 18 | 11.5 | 80 | 12 | 125 | 2 | R2 | Microkevlar D |

| CN230 120 E 15 125 R300 D | 12 | 18 | 11.5 | 80 | 12 | 125 | 2 | R3 | Microkevlar D |

| CN230 120 E 15 150 R050 D | 12 | 18 | 11.5 | 100 | 12 | 150 | 2 | R0.5 | Microkevlar D |

| CN230 120 E 15 150 R100 D | 12 | 18 | 11.5 | 100 | 12 | 150 | 2 | R1 | Microkevlar D |

| CN230 120 E 15 150 R200 D | 12 | 18 | 11.5 | 100 | 12 | 150 | 2 | R2 | Microkevlar D |

| CN230 120 E 15 150 R300 D | 12 | 18 | 11.5 | 100 | 12 | 150 | 2 | R3 | Microkevlar D |

| CN230 160 E 15 100 R050 D | 16 | 24 | 15.5 | 50 | 16 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 160 E 15 100 R100 D | 16 | 24 | 15.5 | 50 | 16 | 100 | 2 | R1 | Microkevlar D |

| CN230 160 E 15 100 R200 D | 16 | 24 | 15.5 | 50 | 16 | 100 | 2 | R2 | Microkevlar D |

| CN230 160 E 15 100 R300 D | 16 | 24 | 15.5 | 50 | 16 | 100 | 2 | R3 | Microkevlar D |

| CN230 160 E 15 100 R400 D | 16 | 24 | 15.5 | 50 | 16 | 100 | 2 | R4 | Microkevlar D |

| CN230 160 E 15 125 R050 D | 16 | 24 | 15.5 | 80 | 16 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 160 E 15 125 R100 D | 16 | 24 | 15.5 | 80 | 16 | 125 | 2 | R1 | Microkevlar D |

| CN230 160 E 15 125 R200 D | 16 | 24 | 15.5 | 80 | 16 | 125 | 2 | R2 | Microkevlar D |

| CN230 160 E 15 125 R300 D | 16 | 24 | 15.5 | 80 | 16 | 125 | 2 | R3 | Microkevlar D |

| CN230 160 E 15 125 R400 D | 16 | 24 | 15.5 | 80 | 16 | 125 | 2 | R4 | Microkevlar D |

| CN230 160 E 15 150 R050 D | 16 | 24 | 15.5 | 100 | 16 | 150 | 2 | R0.5 | Microkevlar D |

| CN230 160 E 15 150 R100 D | 16 | 24 | 15.5 | 100 | 16 | 150 | 2 | R1 | Microkevlar D |

| CN230 160 E 15 150 R200 D | 16 | 24 | 15.5 | 100 | 16 | 150 | 2 | R2 | Microkevlar D |

| CN230 160 E 15 150 R300 D | 16 | 24 | 15.5 | 100 | 16 | 150 | 2 | R3 | Microkevlar D |

| CN230 160 E 15 150 R400 D | 16 | 24 | 15.5 | 100 | 16 | 150 | 2 | R4 | Microkevlar D |

| CN230 200 E 15 100 R050 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R0.5 | Microkevlar D |

| CN230 200 E 15 100 R100 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R1 | Microkevlar D |

| CN230 200 E 15 100 R200 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R2 | Microkevlar D |

| CN230 200 E 15 100 R300 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R3 | Microkevlar D |

| CN230 200 E 15 100 R400 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R4 | Microkevlar D |

| CN230 200 E 15 100 R500 D | 20 | 30 | 19.5 | 50 | 20 | 100 | 2 | R5 | Microkevlar D |

| CN230 200 E 15 125 R050 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R0.5 | Microkevlar D |

| CN230 200 E 15 125 R100 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R1 | Microkevlar D |

| CN230 200 E 15 125 R200 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R2 | Microkevlar D |

| CN230 200 E 15 125 R300 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R3 | Microkevlar D |

| CN230 200 E 15 125 R400 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R4 | Microkevlar D |

| CN230 200 E 15 125 R500 D | 20 | 30 | 19.5 | 80 | 20 | 125 | 2 | R5 | Microkevlar D |

| CN230 200 E 15 150 R050 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R0.5 | Microkevlar D |

| CN230 200 E 15 150 R100 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R1 | Microkevlar D |

| CN230 200 E 15 150 R200 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R2 | Microkevlar D |

| CN230 200 E 15 150 R300 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R3 | Microkevlar D |

| CN230 200 E 15 150 R400 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R4 | Microkevlar D |

| CN230 200 E 15 150 R500 D | 20 | 30 | 19.5 | 100 | 20 | 150 | 2 | R5 | Microkevlar D |

| SLOTTING | ||||||||||||

| ISO | SMG | ap*Dc | ae*Dc | Vc | Paremeters | Zn = 2 | ||||||

| GROUP |

|

(m / min) | 1.5 | 3 | 6 | 10 | 12 | 16 | 20 | |||

| P |

P

1 - 2

|

0.10 | 1.00 | 122 | n (rev/min) | 25890 | 12940 | 6470 | 3880 | 3240 | 2430 | 1940 |

| fz (mm) | 0.005 | 0.011 | 0.022 | 0.036 | 0.043 | 0.058 | 0.072 | |||||

| 104 - 140 | vf (mm/min) | 258 | 258 | 258 | 258 | 258 | 258 | 258 | ||||

|

P

3 - 4

|

0.20 | 1.00 | 61 | n (rev/min) | 12940 | 6470 | 3240 | 1940 | 1620 | 1210 | 970 | |

| fz (mm) | 0.003 | 0.007 | 0.013 | 0.022 | 0.027 | 0.036 | 0.045 | |||||

| 43 - 79 | vf (mm/min) | 78 | 90 | 85 | 90 | 90 | 90 | 90 | ||||

|

E

5 - 6

|

0.20 | 1.00 | 30 | n (rev/min) | 6370 | 3180 | 1590 | 950 | 800 | 600 | 480 | |

| fz (mm) | 0.003 | 0.006 | 0.012 | 0.019 | 0.023 | 0.031 | 0.038 | |||||

| 12 - 49 | vf (mm/min) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | ||||

| M |

M

8 - 9

|

0.50 | 1.00 | 98 | n (rev/min) | 20800 | 10400 | 5200 | 3120 | 2600 | 1950 | 1560 |

| fz (mm) | 0.003 | 0.005 | 0.011 | 0.018 | 0.021 | 0.028 | 0.035 | |||||

| 88 - 107 | vf (mm/min) | 125 | 125 | 125 | 125 | 125 | 125 | 125 | ||||

|

M

10 - 11

|

0.30 | 1.00 | 76 | n (rev/min) | 16130 | 8060 | 4030 | 2420 | 2020 | 1510 | 1210 | |

| fz (mm) | 0.002 | 0.005 | 0.010 | 0.016 | 0.019 | 0.026 | 0.032 | |||||

| 67 - 85 | vf (mm/min) | 64 | 64 | 64 | 64 | 64 | 64 | 77 | ||||

| K |

K

12 - 13

|

0.30 | 1.00 | 82 | n (rev/min) | 17400 | 8700 | 4350 | 2610 | 2180 | 1630 | 1310 |

| fz (mm) | 0.007 | 0.014 | 0.028 | 0.046 | 0.056 | 0.074 | 0.093 | |||||

| 64 - 101 | vf (mm/min) | 174 | 175 | 174 | 174 | 174 | 174 | 175 | ||||

|

K

14 - 15

|

0.20 | 1.00 | 44 | n (rev/min) | 9340 | 4670 | 2330 | 1400 | 1170 | 880 | 700 | |

| fz (mm) | 0.004 | 0.008 | 0.016 | 0.027 | 0.033 | 0.044 | 0.054 | |||||

| 26 - 62 | vf (mm/min) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||||

| N | N16 | 1.00 | 1.00 | 213 | n (rev/min) | 45200 | 22600 | 11300 | 6780 | 5650 | 4240 | 3390 |

| fz (mm) | 0.005 | 0.011 | 0.022 | 0.036 | 0.043 | 0.058 | 0.072 | |||||

| 122-305 | vf (mm/min) | 490 | 490 | 490 | 490 | 490 | 490 | 490 | ||||

| N17 | 1.00 | 1.00 | 213 | n (rev/min) | 45200 | 22600 | 11300 | 6780 | 5650 | 4240 | 3390 | |

| fz (mm) | 0.005 | 0.011 | 0.022 | 0.036 | 0.043 | 0.058 | 0.072 | |||||

| 122-305 | vf (mm/min) | 490 | 490 | 490 | 490 | 490 | 490 | 490 | ||||

| S |

S

19

|

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 55 | 55 | 55 | 55 | 55 | 55 | 55 | ||||

|

S

20

|

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 | |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 55 | 55 | 55 | 55 | 55 | 55 | 55 | ||||

|

S

21

|

0.20 | 1.00 | 21 | n (rev/min) | 4460 | 2230 | 1110 | 670 | 560 | 420 | 330 | |

| fz (mm) | 0.005 | 0.009 | 0.018 | 0.030 | 0.036 | 0.048 | 0.060 | |||||

| 12 - 30 | vf (mm/min) | 55 | 55 | 55 | 55 | 55 | 55 | 55 | ||||

|

S

22

|

0.20 | 1.00 | 34 | n (rev/min) | 7220 | 3610 | 1800 | 1080 | 900 | 680 | 540 | |

| fz (mm) | 0.004 | 0.008 | 0.017 | 0.028 | 0.034 | 0.045 | 0.056 | |||||

| 16 - 52 | vf (mm/min) | 121 | 121 | 121 | 121 | 121 | 122 | 121 | ||||

XIAN COULOIR CUTTER CO., LTD

XIAN COULOIR CUTTER CO., LTD

Adress:4FL, BINTIAN MANSION, YONGLE INDUSTRIAL PARK, JINGHE NEW CITY OF XIXIAN NEW AREA, SHAANXI PROVINCE, CHINA. 713702

TEL:86-29-38952897/15091858296

FAX:86-29-38952897

ICP Record Number:Shaanxi ICP No. 19008760-1